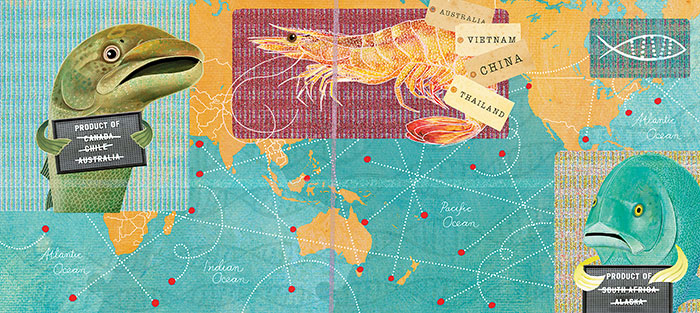

New initiatives are targeting mislabelling, fraud and quality control throughout the supply chain

Illustration: Sonia Kretschmer

Illustration: Sonia KretschmerBy Annabel Boyer

Many Australian seafood producers target high-value markets, achieving premium prices by trading internationally on Australia’s reputation as a ‘clean and green’ country with one of the world’s most rigorous fisheries management systems.

Consumers also rely on Australia’s reputation for safe, quality seafood and, increasingly, for seafood recognised as sustainable. But how easy is it to verify that the fish you’re buying is what it’s supposed to be? Whole fish of similar species can be difficult to tell apart, and a single species can have multiple colloquial names, or multiple species the same common name, which can lead to unintended mislabelling.

Once a fish has been skinned and filleted, distinguishing different species can be virtually impossible. Even fillets from the same fish may look like they come from different fish, depending on who has done the filleting.

In addition to the unintentional mislabelling, deliberate seafood substitution and fraud are reported to be widespread. A recent publication by Oceana, an ocean conservation group – Deceptive Dishes: Seafood Swaps Found Worldwide – produced to inform a US presidential taskforce to address illegal, unreported and unregulated (IUU) fishing and seafood fraud, found seafood fraud in all of the 55 countries investigated. It reports that, on average, one in five of 25,000 samples of seafood tested worldwide were mislabelled. While the report suggests that in Australia the problem is more often one of identity confusion, intentional mislabelling cannot always be ruled out.

Two strategies that can be used to address identification issues are biologically based product validation and information-based supply chain traceability systems. These approaches often work in tandem and are becoming more affordable and accessible as a result of technological advances.

Biological approach

Every organism has a unique genetic code, so DNA has the advantage of being tamper-proof. However, the costs of DNA analysis have until recently been too high to be commercially viable. But that is changing. New technology is making DNA analysis more affordable and accurate. A recent collaboration between the CSIRO and the Marine Stewardship Council (MSC) has been used to validate an individual fish, its species and the population or stock it came from, which in turn can identify where it was caught.

Geneticist Peter Grewe, population researcher Campbell Davies and the CSIRO are involved in a project using new techniques of DNA analysis to validate tuna stocks for the MSC.

Jaco Barendse, MSC’s product integrity traceability manager, says the research “was initiated in 2013 due to a need of the MSC to be able to confirm the origin of certified tuna, and therefore be able to detect any substitution should it occur”.

The next-generation DNA sequencing techniques used in the project have been able to identify ‘population signatures’ for discrete populations of Yellowfin Tuna in particular locations. The project sampled tuna from three different locations in the Pacific Ocean.

“This population signature has allowed for the ability to identify the point of origin of a fish with almost 100 per cent accuracy,” Peter Grewe says. The research also points out the fact that low development costs and high throughput of these techniques mean they can be applied on large enough scales to be relevant to fisheries assessment and management.

The research demonstrated that the Yellowfin Tuna population in the Pacific Ocean is made up of three discrete biological populations rather than just one, as previously thought. Thus the CSIRO findings have implications for management of the billion-dollar Yellowfin Tuna fisheries, which have been managed on geopolitical lines. New management strategies may be needed to better support the sustainability of separate biological stocks.

Campbell Davies says the wider use of DNA to validate both species and provenance will be contingent on a reference library of genetic information with which to compare samples. “If we look at the oceans as a jigsaw puzzle, three pieces have been put together. The next step is a global survey.”

Jaco Barendse says the next step in the MSC project is to confirm the origin of Skipjack Tuna as well as to test the technique on canned tuna products. The MSC already conducts random DNA tests on many MSC-labelled products. However, this has been challenging for cooked and canned products, from which it has proven difficult to extract identifiable DNA. Much of the most commonly consumed and valuable fish species in the world, such as tuna and salmon, are consumed in canned products.

However, Peter Grewe says a proof-of-concept project that demonstrates DNA of sufficient quality for analysis can be extracted from these processed products has already been completed. The next step will be to test this concept more widely and ultimately determine its commercial viability.

Trace element fingerprinting

Trace element fingerprinting (TEF) is a technique that was originally developed to authenticate diamonds from particular parts of Western Australia.

It has since been adapted for agriculture by the Australian pork industry, which has developed a tool called Physi-TraceTM to identify the provenance of Australian-grown pork. It does this by matching trace mineral markers from within the sample (this could include flesh, bones, shells or hooves) to a producer database and is more than 95 per cent accurate.

Now the prawn industry, Curtin University and the FRDC are set to join forces on a project (FRDC research code: 2016-261) that will test TEF as a method to validate the provenance of Australian prawns, identifying the locations where they have been farmed or fished. TEF has been selected for testing as a validation technique rather than DNA analysis because many prawns grown in South-East Asia come from Australian spawning stock and are likely to have similar genetic markers.

Warren Lewis of Aqua-Marine Marketing says the Australian industry has been concerned for some time that cheaper prawns grown in Vietnam or Thailand have been substituted for local product at the point of retail sale. Substitution has adverse consequences in regard to brand recognition and development if an inferior product is sold under the brand of higher-quality product.

TEF has the potential to trace prawns back to the locations where they were farmed or fished, allowing confirmation of provenance and safe seafood. “In Australia, there is a lot of variation in the environmental conditions where farms are, and this technique could trace back to that,” Warren Lewis says. It will mean that producers – both fishers and farmers – can validate their product to ensure Australian prawns and different brands are being correctly labelled, valued and recognised.

Traceability

Full supply chain traceability means being able to track a product through the supply chain to its source. It is another approach that can be used to validate product identity, at the same time as it protects food safety and quality.

Seafood is the world’s most traded commodity; the more players handling the product, the more difficult it becomes to confirm what it is and where it came from. From fisher to wholesalers and processors, food service distributors, restaurants and retailers, it’s often a long way before some products reach the consumer.

For businesses that supply food it is more important than ever to be able to track a product. This is as much true to ensure everything flows smoothly as it is to ensure contamination or food safety issues can be identified should something go awry.

Any system of traceability requires good organisation, communication, record-keeping and management to give certainty – and control – over the location and handling of a product through the supply chain.

New forms of barcoding and tagging are being developed to support seafood traceability. Smartphone technology and cloud computing are combining to make it easier to collect, record and access information as a product moves along a supply chain.

Several FRDC projects have investigated the suitability of electronic traceability systems on commercial prawn trawlers in Australia. Systems investigated and underway include radio-frequency identification (RFID) chips – tiny devices that can store and transmit information – along with the application of barcoding of product on trawlers (FRDC research codes: 2012-702 and 2015-711).

Australian Wild Abalone has adopted a brand protection system, developed with support from the FRDC (2009-723). Tiny nickel tags suspended in an ultraviolet-light-sensitive adhesive are attached to the shells of abalone. The tags include a certification mark and an individual export code. An ultraviolet light is then used to scan the tag and validate this high-value, high-quality Australian product.

Tamper-proof tags have also been developed for the Southern Rocklobster fishery (FRDC research code: 2004-412). The development of robust, individually branded and barcoded lobster tags and a functional traceability system allow industry to offer a branded, quality guaranteed product. While individual industry sectors have been active in developing systems for specific products, Australia’s seafood sector as a whole does not have a coherent and overarching policy on traceability.

To that end, a series of workshops on traceability in the seafood industry have been convened by the World Wildlife Fund (WWF) during the past year to look at both traceability best practice and the need for a traceability system in Australia.

Ensuring seafood safety, meeting independent sustainability certification requirements, and protecting the marketing advantages gained from knowing product identity and provenance are among the growing number of drivers for whole-of-chain traceability.

The aim of the WWF workshops is to bring together all stakeholders from along the supply chain to discuss the basic requirements of a traceability system. The ultimate aim is to arrive at a ‘traceability statement’ around which different players in Australia’s seafood sector can base their traceability systems. The FRDC’s Josh Fielding attended the workshops and says they brought together a broad range of stakeholders to discuss the merits of seafood traceability.

FishFace Visual Recognition Technology

The Australian-based arm of international green group The Nature Conservancy (TNC) is testing technology to identify fish caught on fishing boats using visual recognition software.

Peter Mous, from TNC’s Indonesia Fisheries Conservation Program, says the idea for the FishFace recognition program came about because it proved difficult to train quality control personnel in diverse fisheries in Indonesia to identify specific fish species.

The technology uses visual recognition software to accurately identify species.

Used on fishing vessels to identify species at the point of capture, FishFace is expected to provide more accurate information to improve sustainable fisheries management.

“So far, we have only tried it out on laboratory scale, with standardised pictures (ie, pictures that were all taken under the same conditions). We provided the software with a set of standardised ‘training’ images of 20 fish species and then provided the software with ‘test’ images of these same 20 fish species. Results were promising; the software got it wrong for only one species, despite the very small set of training images,” says Peter Mous.

The technology is powered by a machine learning engine developed by Swedish firm Refind Technologies. In standard conditions in the lab, photos are taken with a smartphone. However, use on a fishing vessel would require a system that could capture images more quickly and efficiently, he says. TNC won $750,000 funding from the 2016 Google Impact Challenge to further develop the technology, building a library of fish images and to test the technology on fishing vessels. FishFace is being tested in Australia and will be trialled initially in Indonesia’s deep-water Snapper and grouper fisheries, with the potential to be rolled out for fisheries everywhere.

It could also be used to establish traceability by ensuring accuracy at the point of capture, which can then more accurately be validated through the supply chain. The Australian Fisheries Management Authority is also assisting with the project.

FRDC Research Codes: 2004-412, 2009-723, 2015-702, 2015-711